Table of Contents

Overview

Accuracy and efficiency dominate everywhere in the field of cable assembly and electrical production. One basic instrument that greatly increases output and quality is the tinning machine. Electrical cable ends are soldered with these equipment, therefore enhancing conductivity and avoiding fraying.

Whether your company specializes in electronics, automotive, or electrical, knowing the advantages and characteristics of a tinning machine will help you improve product lifetime and simplify processes. This site offers a thorough overview of tinning machines—what they are, how they operate, their varieties, applications, advantages, and purchase factors.

A Tinning machine is what?

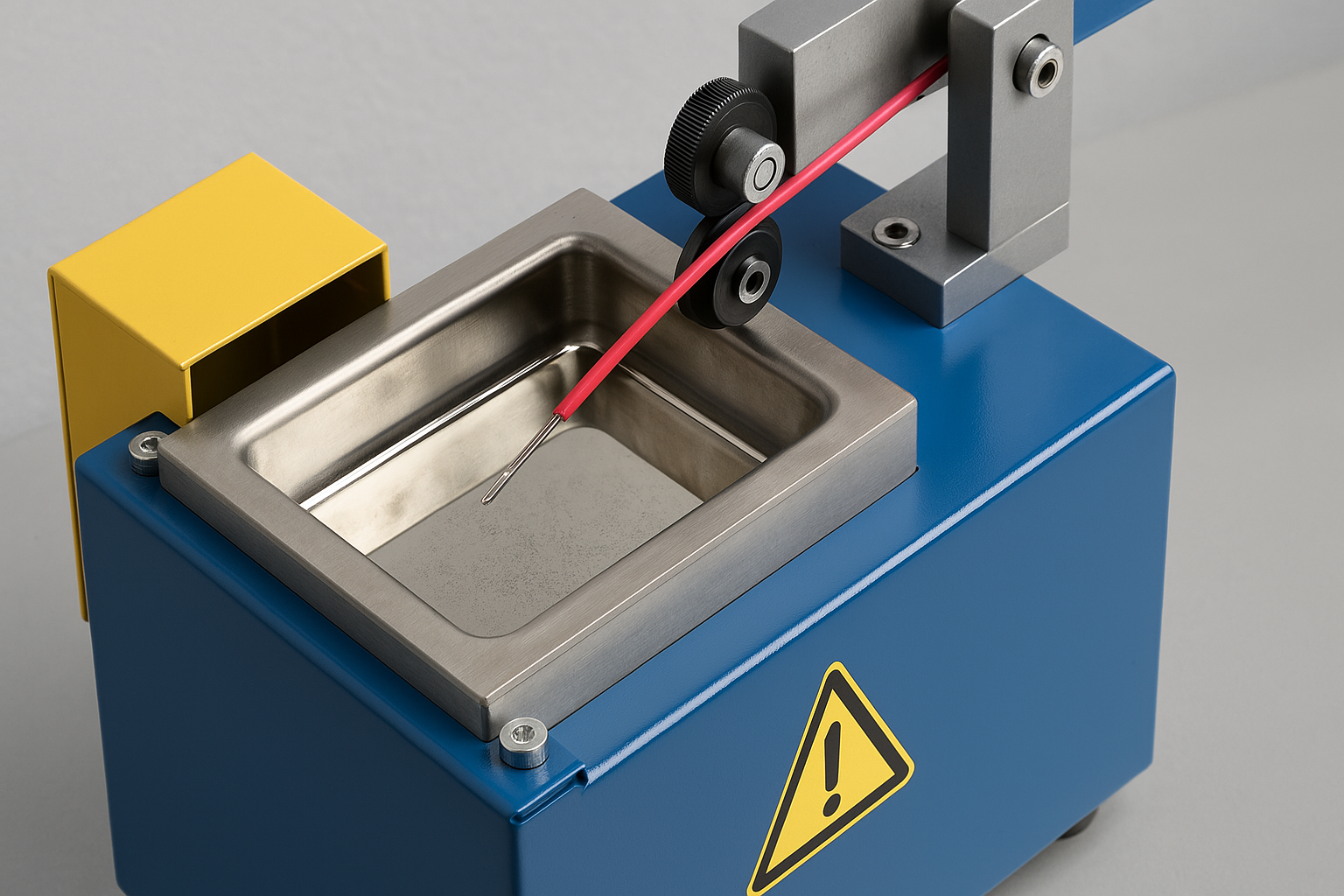

Applied to the stripped ends of electrical wires, a tinning machine is an automated equipment used in thin solder layer application. Known as wire tinning, this procedure improves wire connection dependability, performance, and longevity.

Molten solder coats or dips exposed wire ends to form a smooth coating. This not only stops corrosion but also simplifies solderable wire connections to PCBs, connectors, or terminals.

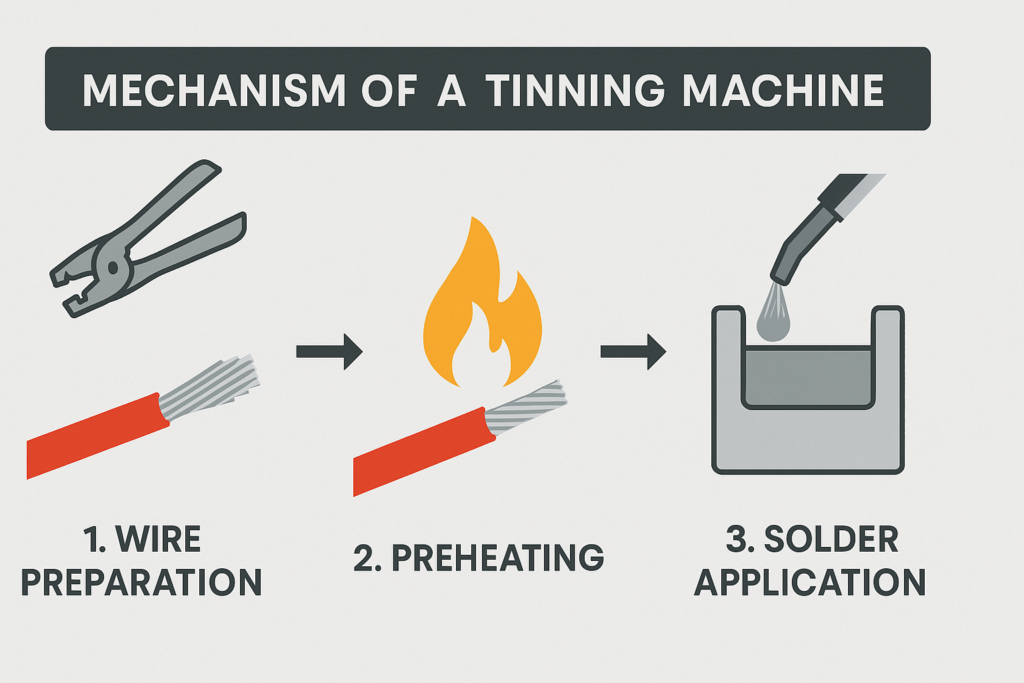

Mechanism of a Tinning Machine

Usually operating in three basic processes, a tinning machine:

- Getting Ready for the Wire

Some machines include built-in wire strippers to cut off insulation from wire ends. - heating before

Preheating the wire helps solder adherence. - Solder Use

The exposed wire forms a consistent tin layer either dipped in molten solder or covered with a heated nozzle.

Among advanced features are a changeable solder bath temperature.

- Rotating wire holders for homogeneous coating

- Systems of integrated fluxing

- Safety sensors and automated shut-off devices

Kinds of Tinning Machines

Various manufacturing settings demand different types of tinning equipment. The most often occurring categories are shown below:

- Handheld Tinning Tools

- call for complete operator handling.

- Perfect for small-scale manufacturing

- Easy to run and reasonably priced

- Semi-automatic tinning equipment

- Operator feeds the wire; soldering is mechanized.

- Faster and more consistently than hand tinning

- Perfect for facilities with mid-sized output

- Completely automated tinning equipment

- Manage the whole process on your own.

- very quick and accurate

- ideal for bulk manufacture in the electronics or automotive sectors

- Tinning machines for hot dips

- Dip wire using molten solder baths.

- great for regularly doing excellent work.

- Tinning Machines for Selective Solders

- solder only particular areas using nozzles.

- Perfect for use in precision projects

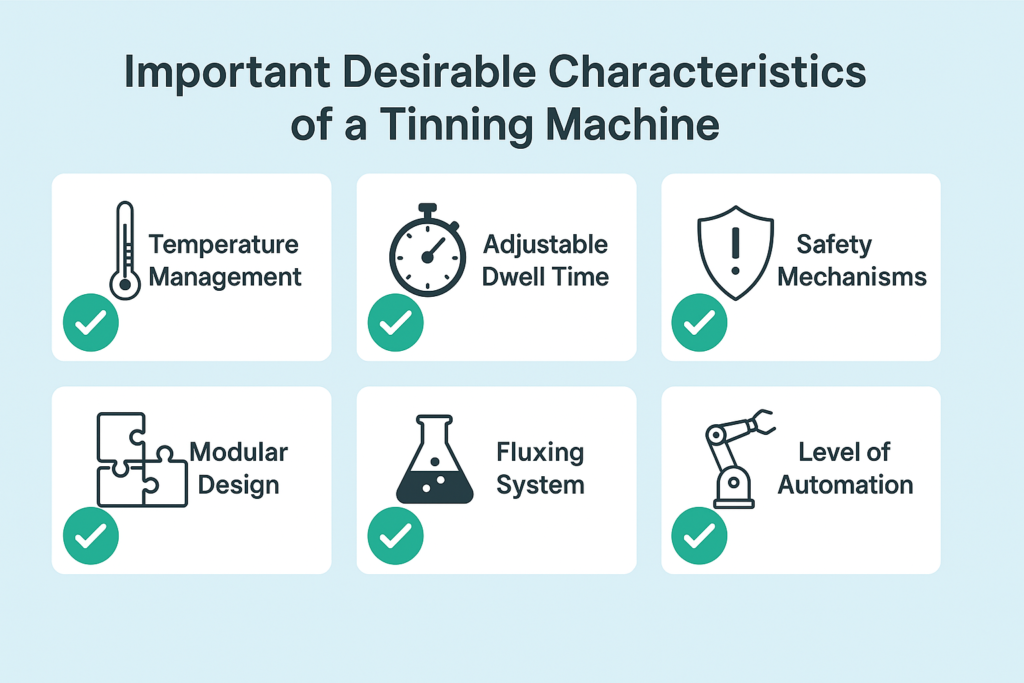

Important Desirable Characteristics of a Tinning Machine

When selecting a tinning machine, give these key considerations top priority:

Temperature Management

Keep soldering temperatures ideal to prevent damage of wire.

Control over the wire’s stay in the solder by changing the adjustable dwell time.

Safety Mechanisms

Auto shut-off, overheat protection, and emergency stop mechanisms.

Module Design

Replacing parts and removable solder pots help to simplify maintenance.

Fluxing System guarantees improved wire coating and helps solder adherence.

Level of Automation:

Based on your need, decide between manual, semi-automatic, or totally automatic.

Tinning Machines’ Uses

Many different sectors employ tinning machines:

Manufacturing Electronics

Before PCB manufacture, tinning wires.

Automotive Industry

ready wire harnesses for strong vehicle communication networks.

Defense and Aerospace

Applied in high dependability mission-critical wire.

Telecommunications Tinning copper wires for effective signal distribution.

Applied in the manufacturing of appliances, handheld tools, and devices, consumer electronics

Top Five advantages of a tinning machine:

- better electrical conductivity

More electrical performance is guaranteed by uniform tin layers. - Oxidation Resilience

stops oxidation, hence increasing wire lifetime. - Continuous Results

Machines provide consistent tinning and help to lower human mistake. - Automation of faster production greatly boosts output.

- Enhanced Bonds

Particularly in demanding surroundings, tinned wires are dependable and strong.

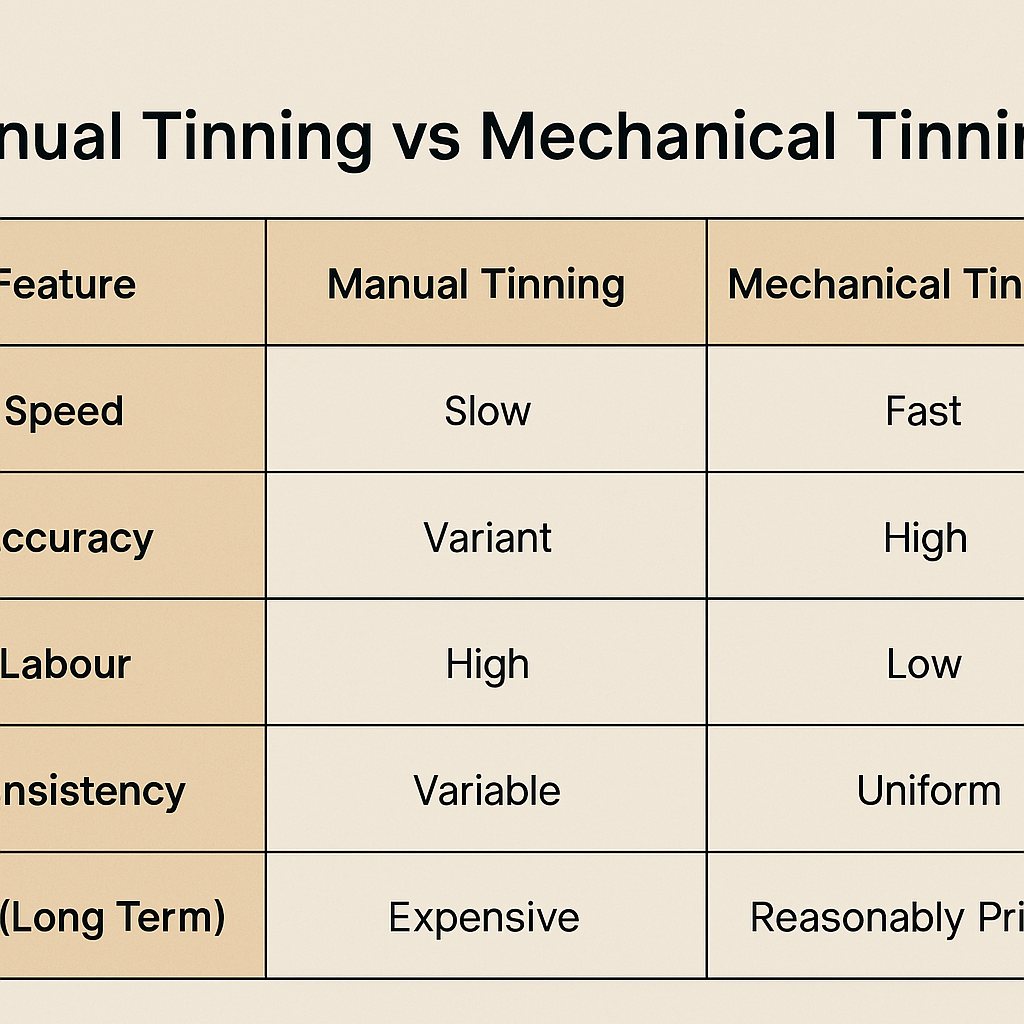

Manual Tinning vs Mechanical Translation

| Manual Tinning | Machine feature for tinning |

|---|---|

| Tinning: Slow | Fast |

| Accuracy | Variant |

| Labor | high |

| Consistency | Variable |

| Cost (Long Term) | Expensive |

How to Select the Appropriate Tinning Machine

These are the main elements guiding your choice of tinning machine for your configuration:

- Production Count:

Select depending on your everyday processing of wires. - Wire Type and Dimensions

Verify fit with your gauge and wire type. - Automaton Level

Completely automated systems cut hand labor and save time. - Brand Equity

Choose names well-known for quality and post-sale assistance. - Guidelines for Safety

Select equipment with approved safety features and requirements.

Top Tinning Machine Production Companies

These are some reputable industry names:

- Schleunger

- Komax

- Eubanks.

- Shenzhen yX

- TEconnection

These companies are well-known for producing enhanced functionality, durability, and accuracy.

Tinning Machine Maintenance Guidelines

To guarantee extended lifespan and best performance:

- Verify the solder pot often.

- Changing solder and flux at advised intervals

- Often times, calibrate temperature settings.

- Eliminate oxidation build-up or wire trash.

- Refer to the manufacturer’s maintenance calendar.

Current Technological Advancements in Tinning Machines

Thanks to technological developments, tinning machines are greener and more intelligent:

- Artificial Intelligence-Based Feedback Systems: Instantaneous quality control

- Energy-efficient solder pots: save electricity.

- IoT Integration: Monitoring from far distances

- Environmentally friendly flux solutions help to lower impact.

FAQs Regarding Tinning Machines

A tinning machine serves what use?

Apply solder to wire ends for longer, corrosion-resistant, and robust connections.

Does tinning become essential?

Indeed, especially in high-vibration or highly reliable surroundings.

Can I run a tinning machine with any wire?

Though most machines accept a variety of wire kinds, always refer to the specs for your model.

A tinning machine costs what?

Manual ones run about $100; fully automated machines can run several thousand.

From where could I get a tinning machine?

Check direct manufacturers like Komax and Schleuniger, markets like Alibaba, or industrial suppliers.

Last Thought

A tinning machine makes sense for companies handling soldering or electrical wiring. From improving manufacturing efficiency to raising product quality, this equipment streamlines wire preparation for several different sectors.

Knowing its varieties, advantages, and features will help you select a machine within your budget and size. And with consistent maintenance and the newest ideas, your operations will remain ahead in the competitive manufacturing scene of today.

2 thoughts on “Tinning Machine: Everything You Need to Know About the Wire Tinning Process”